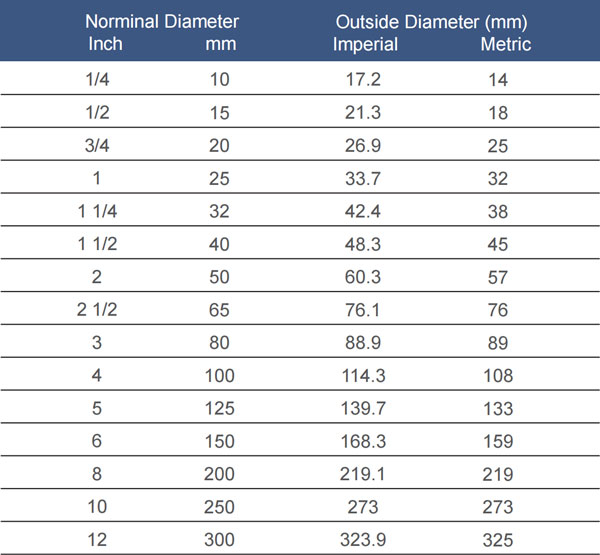

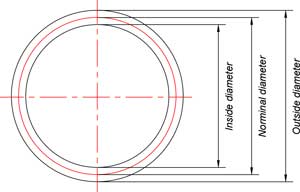

Bellows serve as flexible connectors within piping systems, featuring nominal diameters that match those of the pipes they link.

The dimensions of the bellows are determined by the outer diameter of the connecting pipe.

Various connection methods and pipe size standards contribute to the diverse sizing options available for bellows.

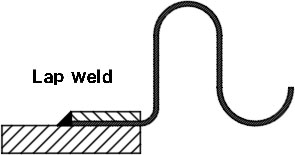

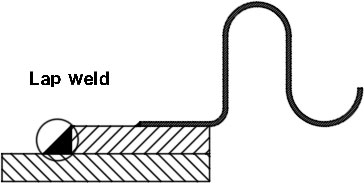

For instance, in the prevalent lap weld method, the bellows’ inner diameter aligns with the outer diameter of the pipe.

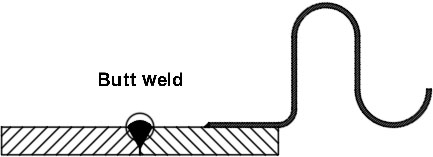

Another common connection method is butt weld. But the bellows, as an elastic seal, is usually made of thin-walled stainless steel. It is not possible to weld it directly to the pipe.

Instead, a common approach involves attaching weld ends on both sides of the bellows to facilitate welding.

Even in this configuration, the inner diameter of the bellows remains congruent with the outer diameter of the pipe.

Another scenario arises when lap welding bellows with welded ends to pipes. In such instances, the inner diameter of the bellows equals the outer diameter of the pipe plus the thickness of the welded end.

Click here to see a list of common bellows sizes.